Friday, April 29, 2011

Wednesday, April 27, 2011

Digital Fabrication Investigation Progress 4/26

I went to Ace today to figure out how to get a lightbulb into the light fixture. Basically, all the parts are seen below. Now I just have to screw into the top piece of the light fixture at the shop so that the power cord connects. That's my goal for tomorrow. I hope I don't electrocute myself and die since this is a homemade electrical concoction... fingers crossed.

Monday, April 25, 2011

Digital Fabrication Investigation Progress 4/25

It's done! Now I just have to fit in the top piece that will hold the lightbulb in place within the light fixture. That's my plan for tomorrow.

Sunday, April 24, 2011

Digital Fabrication Investigation Progress 4/20-4/24

For the past few days, I have been putting the light fixture together. It's almost done! It's just taking longer than expected sanding all the pieces. Tomorrow, I plan on figuring out how to attach the bulb to the top in order to create a hanging fixture.

Tuesday, April 19, 2011

Digital Fabrication Investigation Progress 4/18-4/19

I'm just continuing to sand the pieces and assemble the light fixture.

This is the progress I have so far...

This is the progress I have so far...

Sunday, April 17, 2011

Digital Fabrication Investigation Progress 4/17

I am still in the process of cutting out each piece. Hopefully, the light fixture will be completely assembled within the next few days. I'll post pictures when it's done. Get excited :)

Digital Fabrication Investigation Progress 4/16

Today, I began to cut off the tabs on each individual piece in order to separate them from the piece of plywood. This process takes a while because I also have to sand each notch down a little bit so that they can slide into each other. The CNC leaves one side of the plywood pretty rough, so the pieces don't fit together accordingly if not sanded down. Tomorrow, I plan to start assembling the light fixture.

Friday, April 15, 2011

Digital Fabrication Investigation Progress 4/14-4/15

Yesterday, I started looking into different etching techniques and designs I could use on plexi. Something like the image below would reflect the solid pieces that make up the light fixture while providing a nice blend of solid/void.

Today, I finished cutting out the plywood pieces. However, I need to go back to the shop tomorrow to cut off the tabs that are keeping them attached to the piece of wood they are cut out of (tabs are used so the pieces stay in place while the CNC makes additional cuts within the shape). I plan to assemble all the plywood pieces sometime this weekend.

Today, I finished cutting out the plywood pieces. However, I need to go back to the shop tomorrow to cut off the tabs that are keeping them attached to the piece of wood they are cut out of (tabs are used so the pieces stay in place while the CNC makes additional cuts within the shape). I plan to assemble all the plywood pieces sometime this weekend.

Wednesday, April 13, 2011

Digital Fabrication Investigation Progress 4/13

I signed up for a time slot on Friday to cut the rest of my pieces for the light fixture. As for now, I am continuing to research possibilities to further my design. I'm thinking about adding laser cut components into the spaces between the wood that would filter the light. For instance, I could take thin plexi and etch a design, similar to fritted glass on windows. I'm interested in exploring how connections between different technologies and materials may work to better a project.

Digital Fabrication Midterm Report

Fabricated Light

Abstract:

Experimenting with computer design and CNC manufacture, I plan to create a light fixture at a larger scale that plays with light and shadow. The design will comprise of machine-cut wood components that will later be assembled utilizing the advantages of friction. Through this project, I plan to explore the potential of Rhino software in collaboration with the process of using the CNC. Fabricating individual components that fit together as a three-dimensional sphere is an intriguing design challenge to investigate. How can fabricated modular planes be applied to benefit three-dimensional design?

Introduction:

The background of the CNC machine begins in 1775 when John Wilkinson invented the first manual laid cylinder boring machine, which was one of the first practical machine devices. In 1800, Henry Maudslay developed the metalworking lathe, a machine tool that held the piece of material being worked in a clamp, or spindle, and rotated it so a cutting tool could cut the surface to the desired contour. In 1818, Eli Whitney developed the first milling machine, which operated in much the same manner, except the cutting tool was placed in the rotating spindle. The material was mounted to the machine bed or worktable and was moved about under the cutting tool through the use of hand wheels. Besides being monotonous and physically exhausting work, the ability of the operator to make identical parts was limited. Slight differences in operation resulted in variation of the axis dimensions, which, in turn, created poorly fitting or unusable parts. A means to operate the motions of the machine automatically was needed. Early attempts used a series of cams that moved the tool or worktable through linkages. As the cam rotated, a link followed the surface of the cam face, moving the cutting tool through a series of motions. The cam face was shaped to control the amount of linkage movement, and the rate at which the cam turned controlled the feedrate of the tool. These early machines were difficult to set correctly, but once set, they offered excellent repeatability for their day.

The modern CNC machine grew out of the work of John T. Parons during the late 1940s and early 1950s. After WWII, Parsons was involved in the manufacture of helicopter rotor blades, which gained him knowledge of precise machining of complex shapes. Parsons soon found that by using an early IBM computer, he was able to make much more accurate contour guides than were possible using manual calculations and layouts. Based on this experience, he won an Air Force contract to develop an automatic contour cutting machine to produce large wing section pieces for aircraft. Utilizing a computer card reader and precise servomotor controls, the resulting machine was massive, complicated, and expensive. However, it worked automatically and produced pieces with the high degree of accuracy required by the aircraft industry.

By the 1960s, the price and complexity of automated machines had been reduced to the point where they were applied to other industries. These machines used direct current electric drive motors to manipulate the hand wheels and operate the tools. The motors took electrical instructions from a tape reader, which read a paper tape approximately 1 in (2.5 cm) in width that was punched with a select series of holes. The position and sequence of the holes allowed the reader to produce the necessary electrical impulses to turn the motors at just the precise time and rate, which in effect operated the machine just like the human operator. Simple computers managed the impulses and were often called Numerical Controlled machines. A programmer produced the tape on a typewriter-like machine and the size of the program was determined by the feet of tape needed to be read to produce a specific part.

Today, the modern CNC uses digital codes instead of manual punched tape and is being used to produce a broad range of products. For instance, Liam Hopkins and Richard Sweeney created the Borealis lampshade, a part of a series of lights, which are the results of experiments with computer design and CNC manufacture. Each lampshade comprises of machine cut components, which are assembled and finished by hand in the studio. They also created the light modulator, a computer-generated form that was converted into modular sections cut from birch plywood using a CNC machine. Emphasis was placed on limiting the number of unique module shapes in order to simplify construction. Twenty six unique units are used in total, repeated through the symmetry of form.

KlingStubbins and Tocci used a similar technique to create a custom ceiling in an office building located in Waltham, Massachusetts. Office dA, on the other hand, provided a linear solution to achieve a fluid and playful space within the interior of a restaurant in South Boston. The design leverages the capabilities of the CNC technology to develop a carved out interior space within the wood ribs. As the longitudinal axis emphasizes the seamless surface, the lateral views offer glimpses into the service space above. To highlight this strategy, certain areas of the ceiling "drip" and "slump," acknowledging the location of areas such as exit signs, lighting features, and other details. Therefore, various methods can be applied to cope with and overcome the limitations of the x- and y-axis only cuts the CNC makes.

Project description:

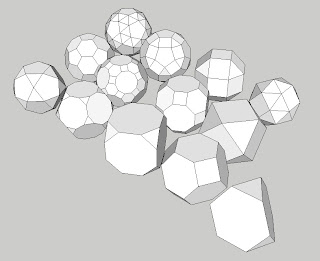

Exploring the capabilities and benefits of the CNC machine in correlation with Rhino will provide a foundation of knowledge in regards to digital fabrication. I chose to design and construct a light fixture of spherical nature as this geometry poses a challenge when constructed on a machine with many limitations. For instance, the CNC only cuts along the x- and y-plane and through material at least 1/8” thick. In addition, the mill is not meant for extremely detailed geometries as the bits are at least 1/8”. Because of these limitations, I strived to design on a larger and less detailed scale. After researching the tools in Rhino as well as the most efficient methods of modeling the desired form, I learned I needed a better understanding of the geometry I want to create. Since SketchUp is the easiest and fastest modeling tool, I decided to quickly experiment with some shapes within that software. I discovered a polyhedron consisting of 32 individual planes of which SketchUp aided in recognizing accurate dimensions and proportions for each plane. These pieces were also designed to fit together through the utilization of notching, which will hold the project together without having to use glue or additional hardware. This technique will provide the greatest strength since friction is more secure than any other type of connection. The required thickness of the material does not allow these notches to overlap, therefore, they had to be carefully planned to work together. After acquiring the appropriate dimensions and importing the final geometry into Rhino software, the CNC will produce the end result. I expect the pieces to be cut accurately in order for the project to be successful.

Working Bibliography:

Autodesk. KlingStubbins & Tocci Building Companies. Retrieved April 10, 2011 from

http://usa.autodesk.com/adsk/servlet/item?siteID=123112&id=12902887

CNC Information. History of CNC. Retrieved April 10, 2011, from

http://www.cncinformation.com/cnc-info-cnc-information-cnc-general-info/cnc-

machine-tool

CNC Milling. Limitations. Retrieved April 5, 2011 from

http://www.cs.cmu.edu/~rapidproto/students.03/dwm3/project2/limitations.html

CNC Milling. Limitations. Retrieved April 5, 2011 from

http://www.cs.cmu.edu/~rapidproto/students.03/dwm3/project2/limitations.html

Lazerian. Borealis Lamp-Shade. Retrieved April 8, 2011, from

http://www.lazerian.co.uk/prod-borealis.php

http://www.sullivancorp.com/history-cnc.htm

http://www.lazerian.co.uk/prod-borealis.php

Saieh, Nico. Arch Daily. BanQ/Office dA. Retrieved April 3, 2011 from

http://www.archdaily.com/42581/banq-office-da/

Sullivan Manufacturing Corporation. The History of CNC. Retrieved April 1, 2011 fromhttp://www.sullivancorp.com/history-cnc.htm

Yatzer. Light Modulator by Lazerian. Retrieved April 8, 2011, from

http://www.yatzer.com/Light-Modulator-by-Lazerian

http://www.yatzer.com/Light-Modulator-by-Lazerian

Tuesday, April 12, 2011

Digital Fabrication Investigation Progress 4/12

Today, I realized the shape I previously designed would not work with 1/4" plywood, so I changed the notches in order to avoid overlapping. Afterwards, I cut out a a few pieces on the CNC and later assembled them. As you can see below, the design worked out pretty well. I had to do quite a bit of sanding to the notches as the CNC is not as accurate as I would like. But, overall I'm happy with the structure and rigidity of the result. Without any glue, it stays locked in. I may finish the polyhedron on the CNC for the final instead of switching to the laser as i previously mentioned I might do. I enjoy the look and strength of the 1/4" plywood, which I found out is a material the laser will not cut.

Monday, April 11, 2011

Digital Fabrication Investigation Progress 4/11

I went out and bought 1/4" plywood today to cut tomorrow on the CNC. Hopefully, everything will go smoothly. I also set up a time to use the laser cutter on Friday. I'm not sure what materials I will choose to use since I'll need a lot of it and all woods besides plywood are pricey.

Sunday, April 10, 2011

Digital Fabrication Investigation Progress 4/10

I split up the individual pieces and imported them into AutoCAD in order to import into Rhino. After speaking with the CNC mill attendants, however, I learned the CNC really isn't meant to be cutting material that is as thin as I need it to be. I'm making an appointment to use the laser cutter instead, which should work out better since it has greater precision, therefore, the pieces will probably fit together better. I still plan on cutting out a few pieces out of wood on the CNC just to experience how it works.

AutoCAD

Rhino

Digital Fabrication Investigation Progress 4/9

Today, I chose a polyhedron I would like to work with and started to examine how I can connect the pieces of the geometry without the use of glue/addition hardware. Below is an image of the solution, which is just a series of tabs that will fit together. Tomorrow, I plan on exporting these shapes into Rhino and cutting them out of wood on the CNC to later assemble.

Digital Fabrication Investigation Progress 4/8

After learning a little bit about scripting, I discovered I needed to know more about the geometry I want to create. Since Sketchup is the easiest and fastest modeling tool, I decided to quickly experiment with some shapes within that software. I'm now looking at different polyhedrons that may be interesting to use. This step in the process will help me gain knowledge of creating 3D geometry on the CNC mill.

Thursday, April 7, 2011

Digital Fabrication Investigation Progress 4/7

Today I continued to research different ways to create the lamp shade in Rhino. I discovered that Rhino features command scripting capabilities that let you automate modeling tasks and create new commands and icons to perform customized functions. Commandscripts can even build a whole model for you, based on different kinds of imported data or scripted procedures. Tomorrow, I'm meeting with someone who will teach me this technique. Stay tuned.

Wednesday, April 6, 2011

Digital Fabrication Investigation Progress 4/6

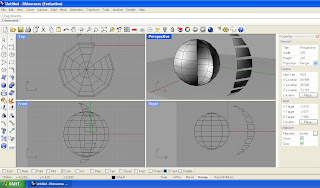

Still trying to familiarize myself with Rhino software, I have been experimenting with different tools to create the shape I am envisioning. With the mesh tool, I created a sphere that is already split up into components. To break these components apart, I extracted the faces and pulled them apart. I am still uncertain how to apply a thickness to the separate pieces and how to manipulate the edges in a way which will allow the sphere to hold together with friction. After I model the sphere in this fashion, I will cut the separate pieces out on the CNC and assemble them. This experiment will give me basic, fundamental knowledge of how a CNC functions as well as the geometry of the sphere. Afterwards, I plan to manipulate the sphere further with punctures while still maintaining the structural nature of the shape.

Tuesday, April 5, 2011

Interactive Architecture Thoughts

What kind of application would thermocrotic paint have in architecture?

Thermocrotic paint can be used on the walls of spaces with a creative function such as educational facilities, studios, or galleries. Such paint allows walls to become large canvases for quick ideas (more so with whiteboard paint) or can become reactive art as people move along the walls, changing the color or texture of the surfaces. I believe it can make people more aware of their presence within a space as well as the presence of simple surfaces.

Arduino- Do you have a better understanding of how sensors work? -Both hardware and software.

After seeing how sensors can change in correlation with the commands of the Grasshopper plugin, I definitely better understand how they work. Using parametrics and constraints, the sensors automatically adjust to the changes made.

How could you apply processing to a component of a building?

Processing can be applied to a digital or interactive building facade that displays whatever form or activity the designer envisions.

How are the hexbugs we saw today different from the ones that are remote controlled? Is there a different type of interaction? Where else do you see these kind of sensors applied?

The hexbugs differ from remote controlled toys because they contain sensors that allow them to turn when they hit a solid surface. This interaction differs as they are not completely controlled by the individual, but rather by the sensors. These kinds of sensors can be applied to vacuum cleaners or interactive architectural elements.

Thermocrotic paint can be used on the walls of spaces with a creative function such as educational facilities, studios, or galleries. Such paint allows walls to become large canvases for quick ideas (more so with whiteboard paint) or can become reactive art as people move along the walls, changing the color or texture of the surfaces. I believe it can make people more aware of their presence within a space as well as the presence of simple surfaces.

Arduino- Do you have a better understanding of how sensors work? -Both hardware and software.

After seeing how sensors can change in correlation with the commands of the Grasshopper plugin, I definitely better understand how they work. Using parametrics and constraints, the sensors automatically adjust to the changes made.

How could you apply processing to a component of a building?

Processing can be applied to a digital or interactive building facade that displays whatever form or activity the designer envisions.

How are the hexbugs we saw today different from the ones that are remote controlled? Is there a different type of interaction? Where else do you see these kind of sensors applied?

The hexbugs differ from remote controlled toys because they contain sensors that allow them to turn when they hit a solid surface. This interaction differs as they are not completely controlled by the individual, but rather by the sensors. These kinds of sensors can be applied to vacuum cleaners or interactive architectural elements.

Sunday, April 3, 2011

Interactive Architecture

The difference between interactive and reactive architecture is that interaction requires a response on both sides. For instance, a simple motion sensor is reactive as it only responds to the motion of the individual. However, an interactive facade or art piece such as the one below, influences the behavior of the individual as well as it begins to direct how one moves their hand.

Digital Fabrication Investigation Progress

After researching my precedents, I have downloaded Rhino to familiarize myself with the program that is used in collaboration with the CNC mill. I have been experimenting with the various tools within the program that seem to be necessary in creating what I ultimately what I want my final project to be. For instance, different forms and boolean tools created the form below, which I will take further in modeling a more interesting lamp shade that resembles my inspiration images. In the next steps, I plan to experiment with splitting up the sphere in a way that will connect and fit together utilizing friction. As of now, I am trying to learn as much as possible about the most effective ways to output Rhino information to the CNC mill.

Digital Fabrication Case Studies

CNC: KlingStubbins & Tocci office building in Waltham, Massachusetts

Pre-fabricated wood ceiling

Laser Printer: Threefold Architects green home in Richmond Park, London

Steel facade has been perforated by laser resulting in an abstracted foliage design

Pre-fabricated wood ceiling

Laser Printer: Threefold Architects green home in Richmond Park, London

Steel facade has been perforated by laser resulting in an abstracted foliage design

3D Printer: Various Architects Mobile Theater

Model was first tested upon new in-house 3D printer

Water Jet Cutter: Ji i Loubal commercial space in Pilsen, Czech Republic

Precision cutting eliminated the necessity of subsequent finishing. Also, there is an absence of jagged edges, however, allows for the production of complicated edges

Robotics: Facade Muralist Spray

Robotic facade printer shoots balls of paint at surfaces to create a pattern

The printing software calculates the driving coordinates with respect to both perspective and ballistic distortion

Subscribe to:

Comments (Atom)